Awesome

<lasercut.scad>

Module for openscad, allowing 3d models to be created from 2d lasercut parts, with a flat file automatically generated.

Updated, not just lasercut can now pass the parameter milling_bit for CNC machines, for the bit to cut in to the corners.

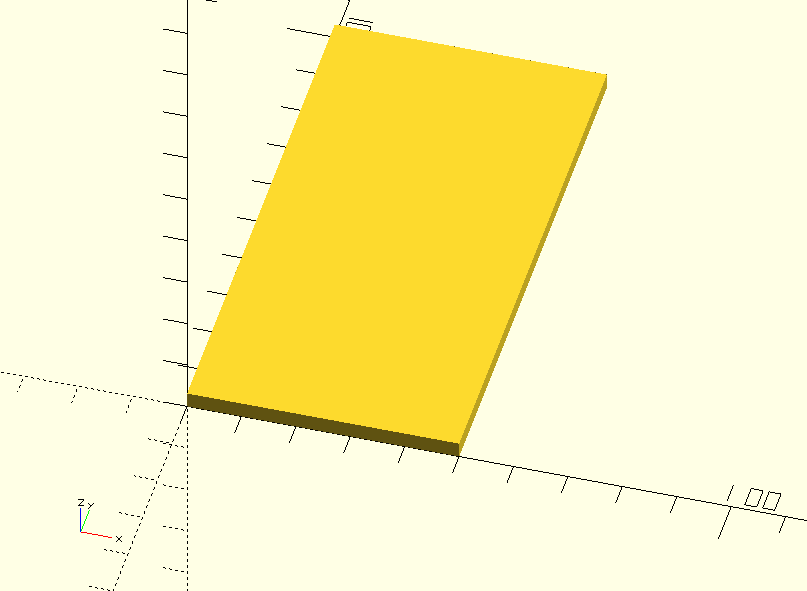

Basic usage

To prepare a simple rectangle use lasercutoutSquare()

include <lasercut.scad>;

thickness = 3.1;

x = 50;

y = 100;

lasercutoutSquare(thickness=thickness, x=x, y=y);

More complex path using the lasercutout()

include <lasercut.scad>;

thickness = 3.1;

x = 50;

y = 100;

points = [[0,0], [x,0], [x,y], [x/2,y], [x/2,y/2], [0,y/2], [0,0]];

lasercutout(thickness=thickness, points = points);

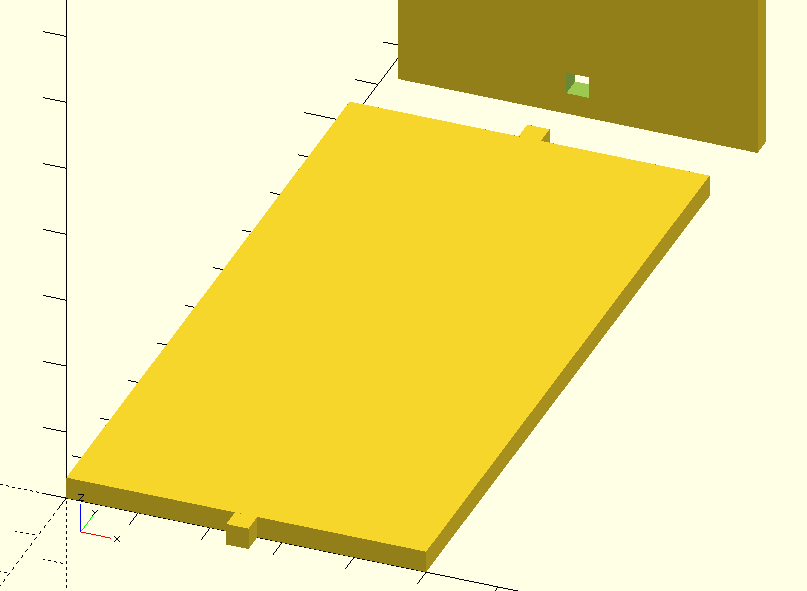

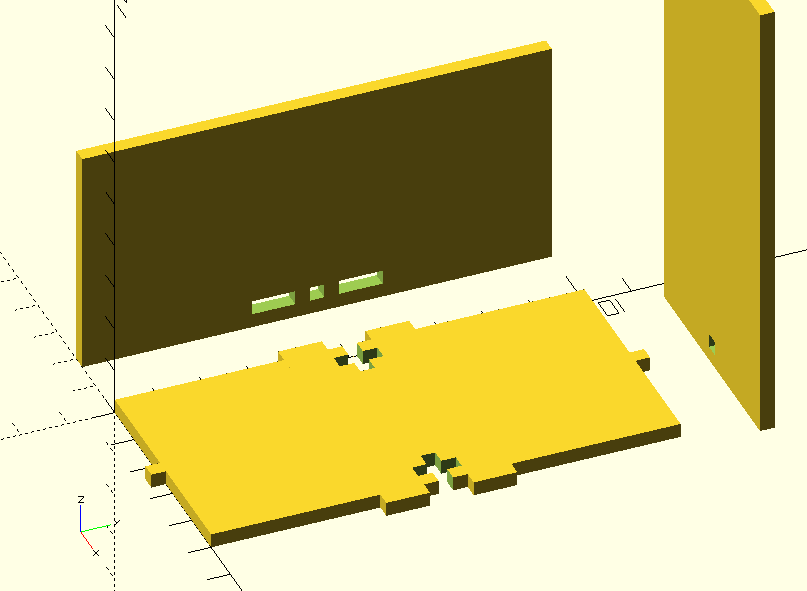

Simple Tab

include <lasercut.scad>;

thickness = 3.1;

x = 50;

y = 100;

lasercutoutSquare(thickness=thickness, x=x, y=y,

simple_tabs=[

[UP, x/2, y],

[DOWN, x/2, 0]

]

);

translate([0,y+20,-thickness]) rotate([90,0,0])

lasercutoutSquare(thickness=thickness, x=x, y=y,

simple_tab_holes=[

[MID, x/2-thickness/2, thickness]

]

);

Captive Nuts

Great for holding laser-cut sheets together.

include <lasercut.scad>;

thickness = 3.1;

nut_flat_width = 9.3;

x = 50;

y = 100;

lasercutoutSquare(thickness=thickness, x=x, y=y,

simple_tabs=[

[UP, x/2, y],

[DOWN, x/2, 0]

],

captive_nuts=[

[LEFT, 0, y/2, nut_flat_width],

[RIGHT, x, y/2, nut_flat_width],

]

);

translate([0,y+20,-thickness]) rotate([90,0,0])

lasercutoutSquare(thickness=thickness, x=x, y=y,

simple_tab_holes=[

[MID, x/2-thickness/2, thickness]

]

);

translate([-20,0,0]) rotate([90,0,90])

lasercutoutSquare(thickness=thickness, x=y, y=x,

captive_nut_holes=[

[DOWN, y/2, 0]

]

);

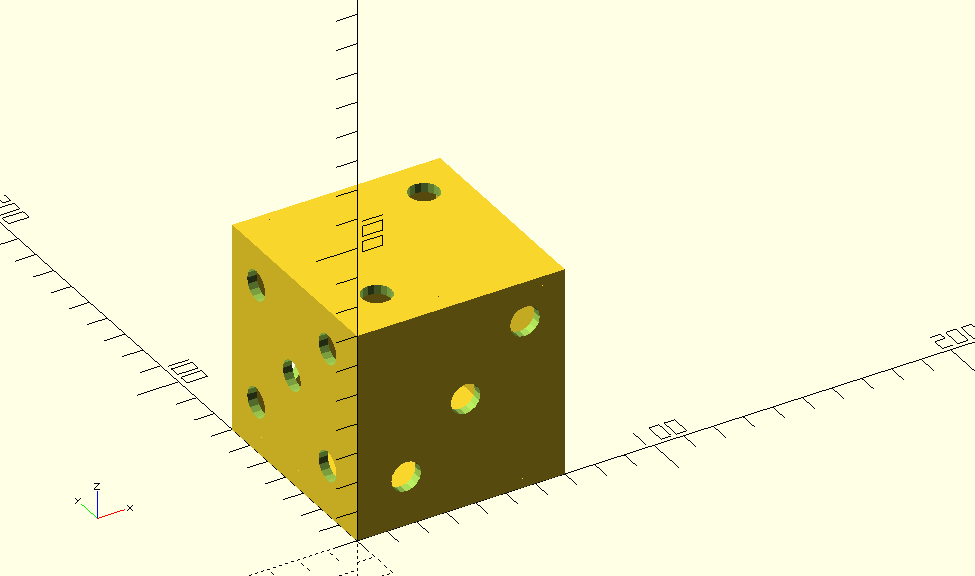

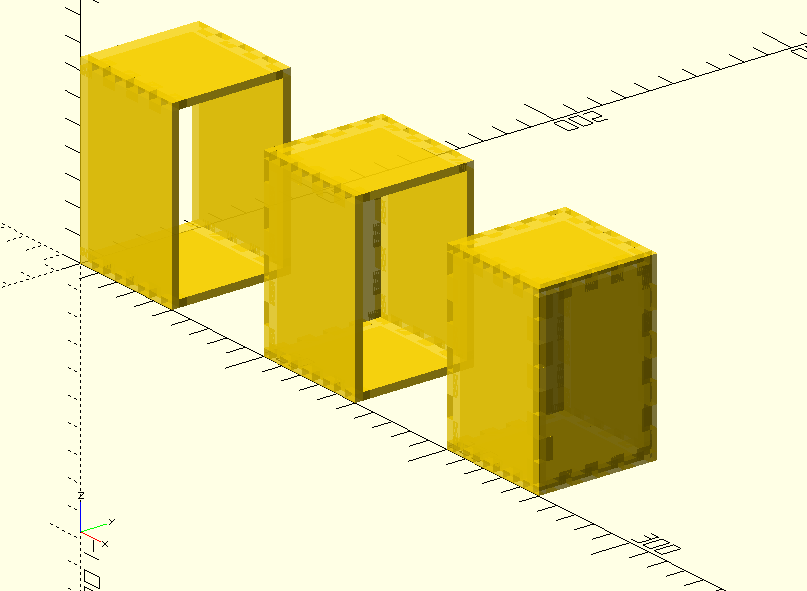

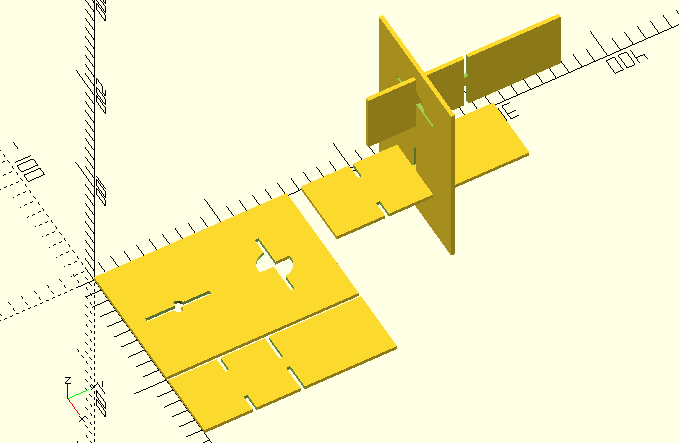

Box

Easy to make a box with four, five or six side. Uses finger joints with the correct alignment to give a flat edge regardless of number of sides.

include <lasercut.scad>;

thickness = 3.1;

x = 50;

y = 50;

z = 75;

for (sides =[4:6])

{

color("Gold",0.75) translate([100*(sides-4),0,0])

lasercutoutBox(thickness = thickness, x=x, y=y, z=z,

sides=sides, num_fingers=4);

}

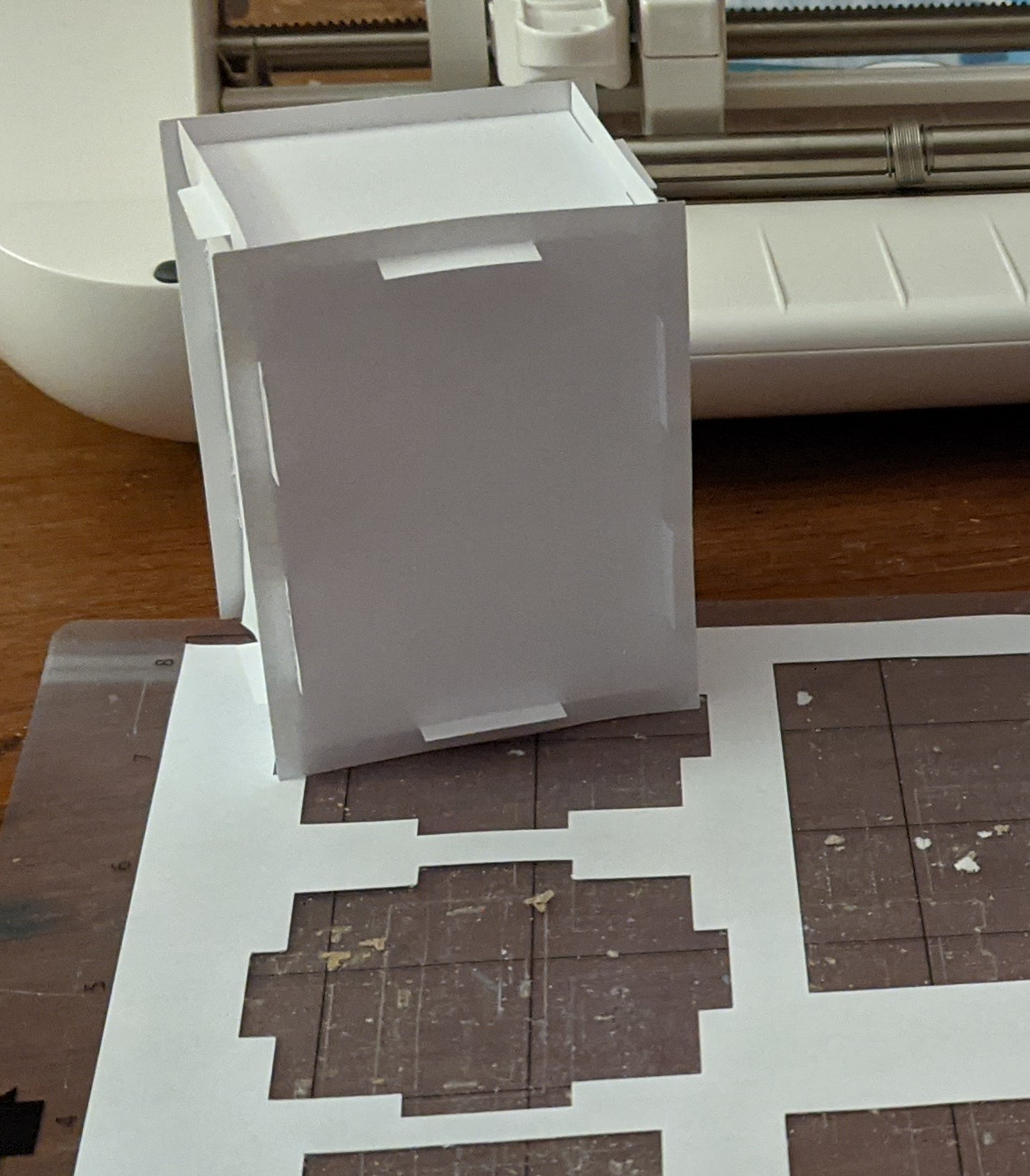

Box for Vinyl Cutters

Easy to make a box with four, five or six side. Uses finger joints with the correct alignment to give a flat edge regardless of number of sides.

include <lasercut.scad>;

lasercutoutVinylBox(x=60, y=50, z=80, thickness=0.2);

More detail on Vinyl Boxes, including infil

Finger Joints

Simple finger joints, (as automatically used in the box above). Parameters are direction, startup tap, even number) so for example [UP, 1, 4] - UP direction, starting with a tab not a gap, four figners.

As suggested in the OpenSCAD forum, bumpy_finger_joints, when printed in wood the dimple will crush a little and ensure a press fit.

include <../lasercut.scad>;

$fn=60;

thickness = 3.1;

x = 50;

y = 100;

lasercutoutSquare(thickness=thickness, x=x, y=y,

bumpy_finger_joints=[

[UP, 1, 4],

[DOWN, 1, 4]

]

);

translate([0,y+20,thickness]) rotate([90,0,0])

lasercutoutSquare(thickness=thickness, x=x, y=y,

finger_joints=[

[UP, 1, 4],

[DOWN, 1, 4]

]

);

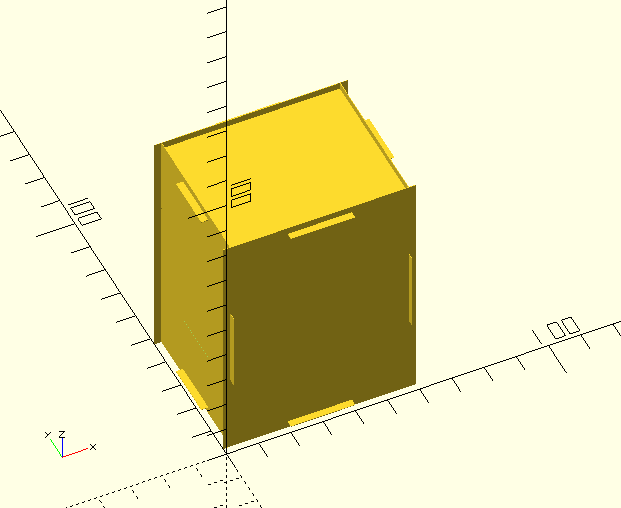

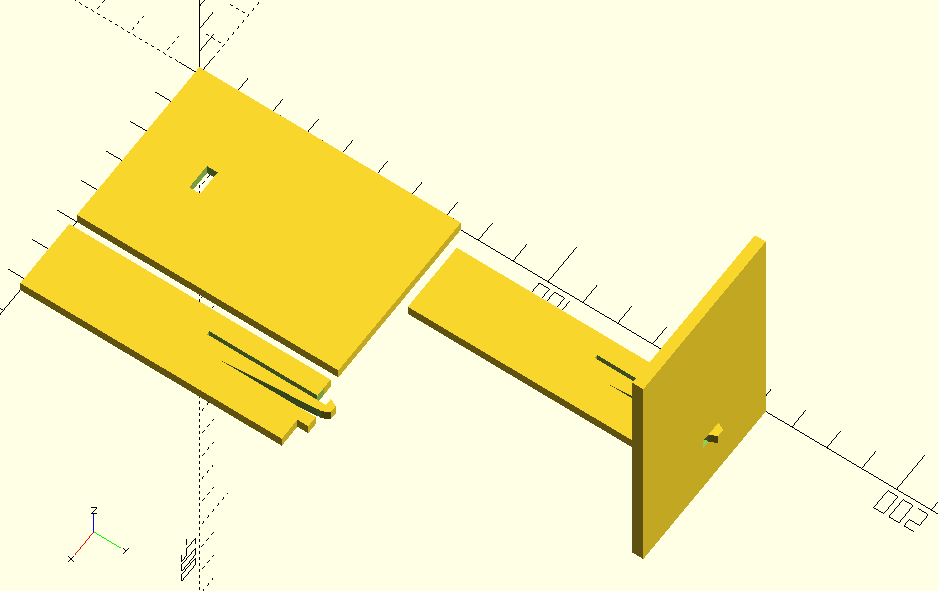

Finger Joints Milled

Simple finger joints, (as automatically used in the box above), but now using the parameter milling_bit for the bit to cut in to the corners.

include <../lasercut.scad>;

$fn=60;

thickness = 3.1;

x = 130;

y = 100;

lasercutoutSquare(thickness=thickness, x=x, y=y,

finger_joints=[

[UP, 0, 2],

[DOWN, 1, 2]

],

milling_bit=3.125

);

translate([0,y+20,thickness]) lasercutoutBox(thickness = thickness, x=x, y=y, z=x/2, sides=5,

num_fingers=2, milling_bit=3.125);

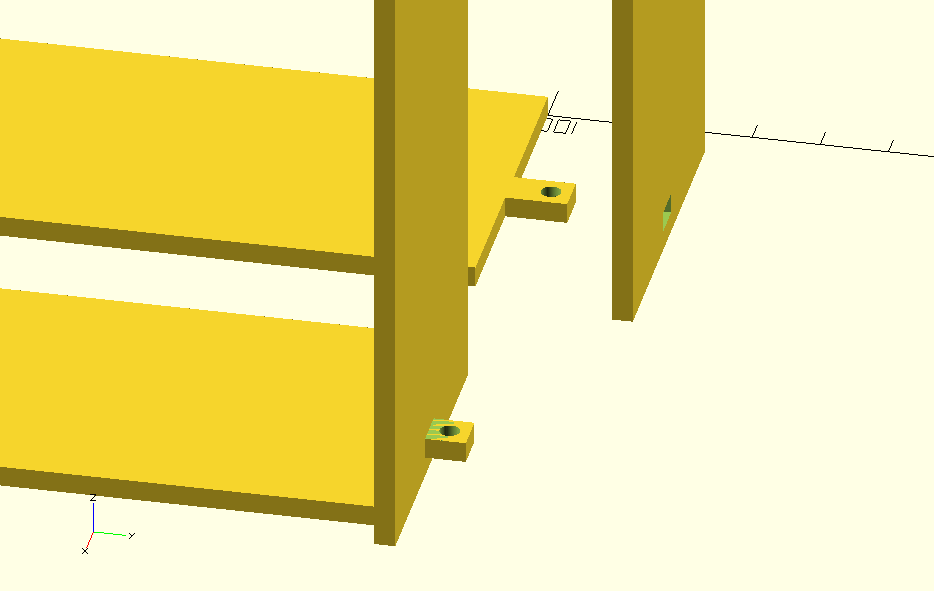

Tabs Held in Place by Screws

Simple through tab, held in place by a screw. Paarameters are direction, x, y, Screw-size) so for example [UP, 50, 100, 3] - for a M3 screw to hold the tab in place.

include <../lasercut.scad>;

thickness = 3.1;

x = 50;

y = 100;

$fn=60;

module base()

{

lasercutoutSquare(thickness=thickness, x=x, y=y,

screw_tabs=[

[UP, x/2, y, 3]

]

);

}

module side()

{

rotate([90,0,0])

lasercutoutSquare(thickness=thickness, x=x, y=y,

screw_tab_holes=[

[MID, x/2-thickness/2, thickness, 3]

]

);

}

translate([0,0,0]) base();

translate([0,y+thickness+20,-thickness]) side();

translate([x+20,0,0]) base();

translate([x+20,y+thickness,-thickness]) side();

Twist Fit

Example joint, copied with permission from http://msraynsford.blogspot.co.uk/2012/06/panel-joinery-10.html from Martin Raynsford's Blog. This joint is formed by placing one part through the other and rotating it into place.

Usual parameters (direction, x, y, spine=optional). Spine is option and determines the length of the central spine, default is three times thickness.

include <../lasercut.scad>;

// From http://msraynsford.blogspot.co.uk/2012/06/panel-joinery-10.html

$fn=60;

thickness = 3.1;

x = 100;

y = 150;

x_beam = 50;

module beam()

{

lasercutoutSquare(thickness=thickness, x=x_beam, y=y,

twist_connect=[

[RIGHT,x/2,y/2],

[RIGHT,x/2,y/4,x_beam/2]

]

);

}

module crossBeam()

{

rotate([90,0,0])

lasercutoutSquare(thickness=thickness, x=x, y=y,

twist_holes=[

[RIGHT, x/2, y*3/4, x_beam, x_beam/2],

[UP, x/2, y/4, x_beam]

]

);

}

rotate([-90,0,0]) crossBeam();

translate([x+thickness,0,0]) beam();

translate([0,y+75,0]) crossBeam();

translate([(x-x_beam)/2,y/2+75-thickness,y*1/4-thickness/2]) rotate([0,0,0]) beam();

translate([x/2-thickness/2,y*3/4+75-thickness,y*3/4+x_beam/2]) rotate([0,90,0]) beam();

Clip

Loosley based upon http://www.deferredprocrastination.co.uk/blog/2013/so-whats-a-practical-laser-cut-clip-size/ the clip and mathcing hole. Should be good for acrylic, mdf but maybe not plywood.

This is quite a long connnector (thickness * 11) to allow the material to bend and clip in place.

include <../lasercut.scad>;

$fn=60;

thickness = 3.1;

x = 50;

y = 75;

x_beam = 20;

module beam()

{

lasercutoutSquare(thickness=thickness, x=x_beam, y=y,

clips=[

[UP,x_beam/2,y]

]

);

}

module crossBeam()

{

rotate([90,0,0])

lasercutoutSquare(thickness=thickness, x=x, y=y,

clip_holes=[

[DOWN, x/2, y/4, x_beam]

]

);

}

rotate([-90,0,0]) crossBeam();

translate([x+thickness,0,0]) beam();

translate([0,y*3/2+50,0]) crossBeam();

translate([(x-x_beam)/2,y/2+50-thickness,y/4]) rotate([0,0,0]) beam();

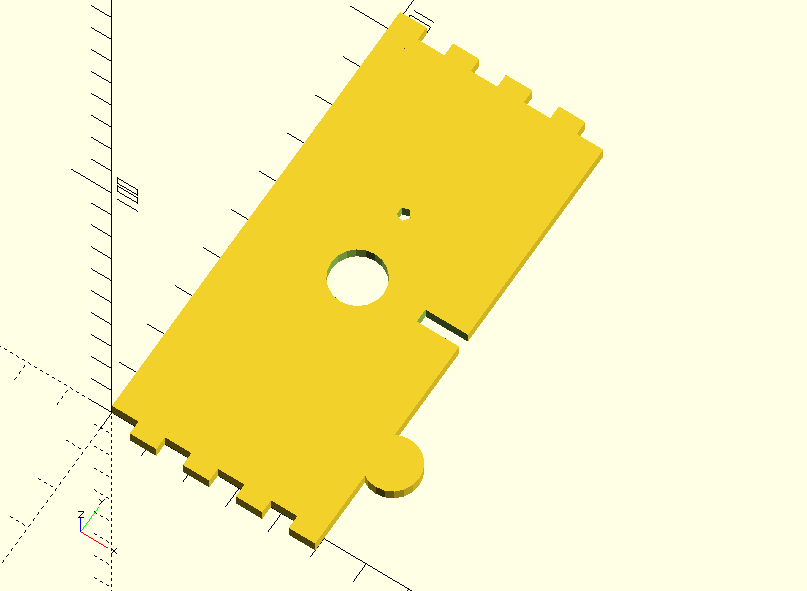

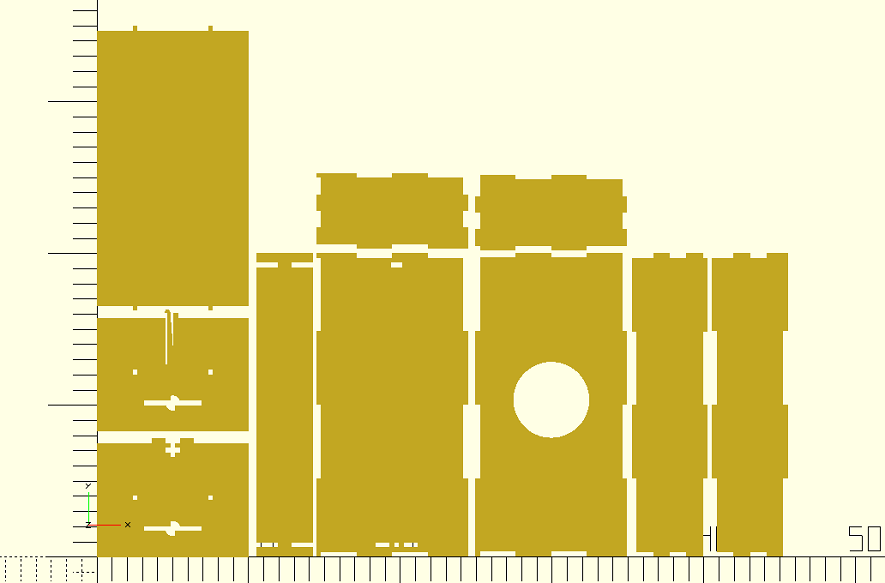

Add or remove circles, make a slit or cut-out a rectangle

Circles are [radius, x, y] Slits are [direction,x,y,length of slit] Cutouts are [x, y, width of cutout, height of cutout]

include <lasercut.scad>;

thickness = 3.1;

x = 50;

y = 100;

r = thickness*2;

lasercutoutSquare(thickness=thickness, x=x, y=y,

finger_joints=[

[UP, 1, 4],

[DOWN, 1, 4]

],

circles_add = [

[r, x+thickness, y/5],

],

circles_remove = [

[r, x/2, y/2],

[1.5, x/2, y*2/3], // Screw-hole

],

slits = [

[RIGHT,x,y/2,10]

],

cutouts = [

[x/6, y/6, thickness*5, thickness*2]

]

);

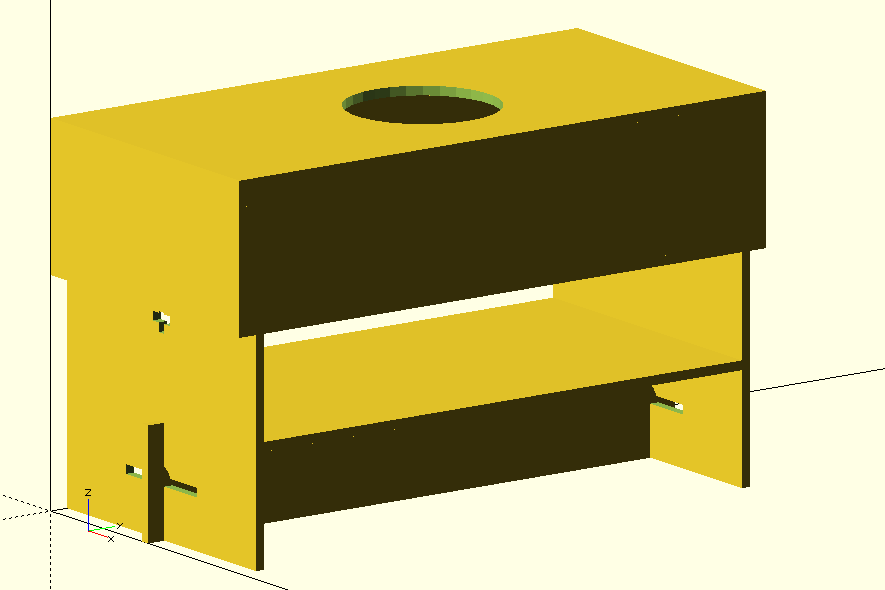

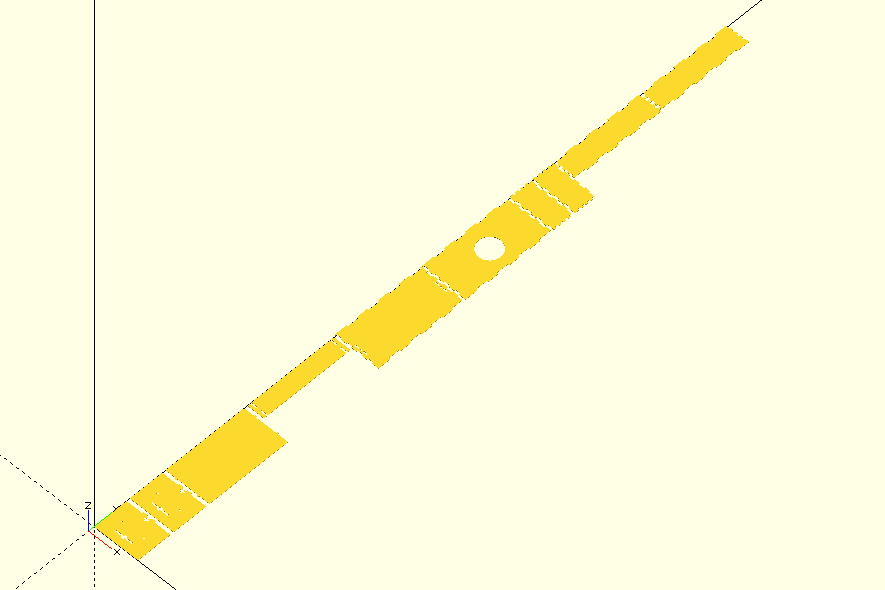

Complex Example

Putting these all together - gives a better example - https://github.com/bmsleight/lasercut/blob/master/examples.scad

Complex Examples - Box is an array

The box is made of 4,5 or 6 sides. Each of the sides can have any of slips, tab or cutout circles.

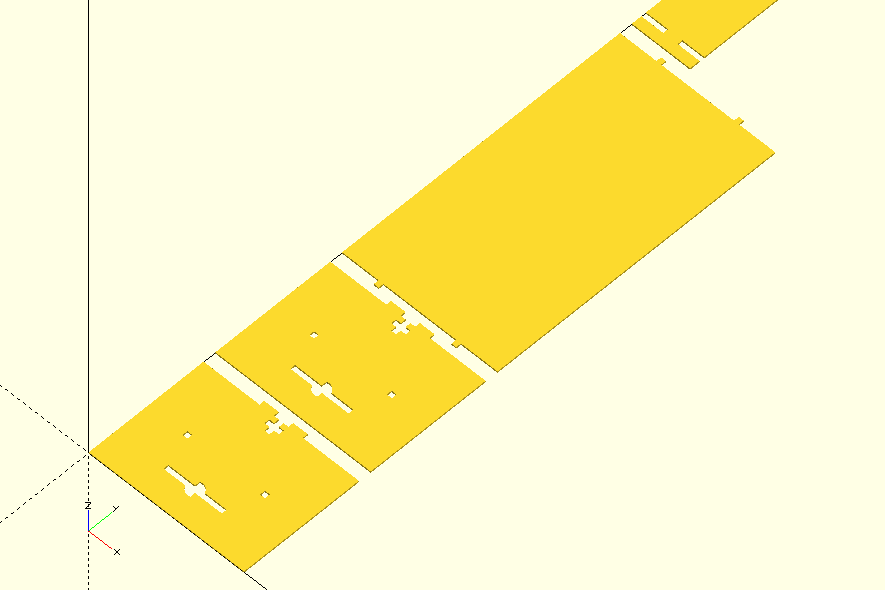

Automatically Generate Files Ready for Laser-Cutter

These models are all very nice, but we need to have a file compatible with our laser-cutter software, such as a dxf or svg file. This can be automated using the included convert-2d.py script, as shown below.

python ./convert-2d.py --keep examples.scad examples_flattened.dxf

This generates two new files:

- examples_flattened.scad

- examples_flattened.dxf

If only the dxf file is desired, the --keep option can be omitted and the generated .scad will not be kept.

examples_flattened.scad

This is an openscad file showing all the shapes along the y-axis.

To adjust the positions of the cut-out, so that are not all along the y-axis the parameter flat_adjust can be used, either in the main files or tweaked in the flattened file. For example flat_adjust = [110, -350]), would put the next peice at 110 in x direction and -250 in y-direction. With just using flat_adjust six times, we get a more practical example.

See examples_flattened_tweak.scad

Which give an arrangement and can be exported to a new dxf file.

Additional Functionality of convert-2d.py

Specify the output file

python ./convert-2d.py examples.scad desired_output_path.scad

Export to a specific format supported by OpenSCAD, e.g., .dxf, .svg, .pdf. The intermediate, flattened scad file will be deleted.

python ./convert-2d.py examples.scad desired_output_path.svg

Export to a specific format supported by OpenSCAD, while keeping the intermediate, flattened scad file.

python ./convert-2d.py --keep examples.scad desired_output_path.svg

Generate a flattened scad file where the pieces have a given thickness, e.g. 3.0mm, This is useful for 3D prints.

python ./convert-2d.py --extrude=3 examples.scad desired_output_path.scad

Generate a flattened scad file where the pieces have a given thickness in a supported 3D format (.stl, .off, .amf, .3mf)

python ./convert-2d.py --extrude=2.5 examples.scad desired_output_path.stl

Specify the path to the OpenSCAD executable

python ./convert-2d.py --openscadbin "C:\Program Files\OpenSCAD\openscad.exe" examples.scad

Specify the path to the lasercut.scad library

python ./convert-2d.py --library lasercut.scad examples.scad desired_output_path.scad

No Laser-Cutter, use Vinyl Cutter

include <lasercut.scad>;

rotate([0,270,0]) lasercutoutVinylBox(x=80, y=60, z=50, thickness=0.2);